Dammam, Saudi Arabia – Eastern Aluminum Extrusion Factory proudly announced that it has achieved a *record* annual sales volume of 20,000 tons in the year 2025, marking a major milestone in the company’s commercial and operational performance. This achievement reflects strong demand for the company’s aluminum extrusion products and the success of its customer-focused sales strategy.

Reaching the 20,000-ton sales mark represents a significant increase compared to previous years and confirms Eastern Aluminum Extrusion Factory’s growing presence in the local and regional markets. The result was supported by reliable product quality, on-time delivery, and close collaboration with key customers in construction, industrial, and architectural applications.

“Our 2025 record of 20,000 tons in sales is a testament to the dedication of our team and the loyalty of our customers across the Kingdom and the wider region,” Eastern Aluminum Extrusion Factory. “We are committed to continuing this growth trajectory by providing high-quality aluminum extrusion solutions and exceptional service.”

Looking ahead, Eastern Aluminum Extrusion Factory plans to further strengthen its market position by expanding its product portfolio, enhancing customer service, and exploring new opportunities in existing and emerging sectors. The company remains committed to supporting Saudi Arabia’s industrial development and to operating with the highest standards of quality, safety, and environmental responsibility.

Aluminum is in most ways the perfect material for constructing windows and doors; it is incredibly strong, light, weather proof and needs very little maintenance to provide years of reliable use. However, Aluminum is also a very good conductor of heat, which means that on its own it provides very poor insulation against the winter weather and provides little protection from the summer sun. In the case of Aluminum windows and doors, its main benefit is to prevent heat transferring from the inner frame to the outer frame and to prevent the cold moving in from the outer to the inner.

The thermal break in Eastern Aluminum windows and doors is created using a polyamide strip between the aluminum exterior and interior elements. The principle for the process is a non-conductive material, usually a rolled polyamide plastic strip, being fabricated between two aluminum components to reduce reciprocal temperature exchanges as well as improving noise reduction, radiation transference and prevention of vibration dampening.

Polyamide is an excellent thermal insulator. The thermal break minimizes the transfer of heat and cold through the aluminum window frame, giving the thermally broken aluminum window excellent insulation properties. Polyamide has very similar expansion rates to aluminum, ensuring Eastern Aluminum Extrusion maintains excellent structural integrity. The thermal barrier conducts up to 1,000 times less heat than aluminum, so it provides a tremendous reduction in heat loss and increases thermal performance. It also has the side effect of making your windows more soundproof, by dampening vibrations between the outer and inner frame.

Eastern Aluminum Extrusion Factory provides the facilities and capabilities for Thermal Break application to create more sophisticated, durable and complex structures by co-joining profiles that the die design process cannot achieve alone.

When your windows have a comfortable temperature, you have a comfortable temperature too.

In a groundbreaking achievement, EAEF announced today that it has successfully sold a staggering 1400 tons of its flagship product, marking a significant milestone in the company's history.

The sales milestone reflects the culmination of strategic planning, innovative marketing tactics, and a dedication to delivering high-quality products to consumers

Commenting on this remarkable achievement, Our Chairman have expressed gratitude to the dedicated team at EAEF for their hard work and commitment to excellence. "This milestone is a testament to our team's unwavering dedication and the trust our customers have placed in us," said by our Chairman

The successful sales of 1400 tons underscore EAEF's position as a leader in the industry and highlight its ability to thrive in a competitive marketplace. Looking ahead, EAEF remains committed to driving innovation, delivering exceptional value to customers, and achieving even greater milestones in the future.

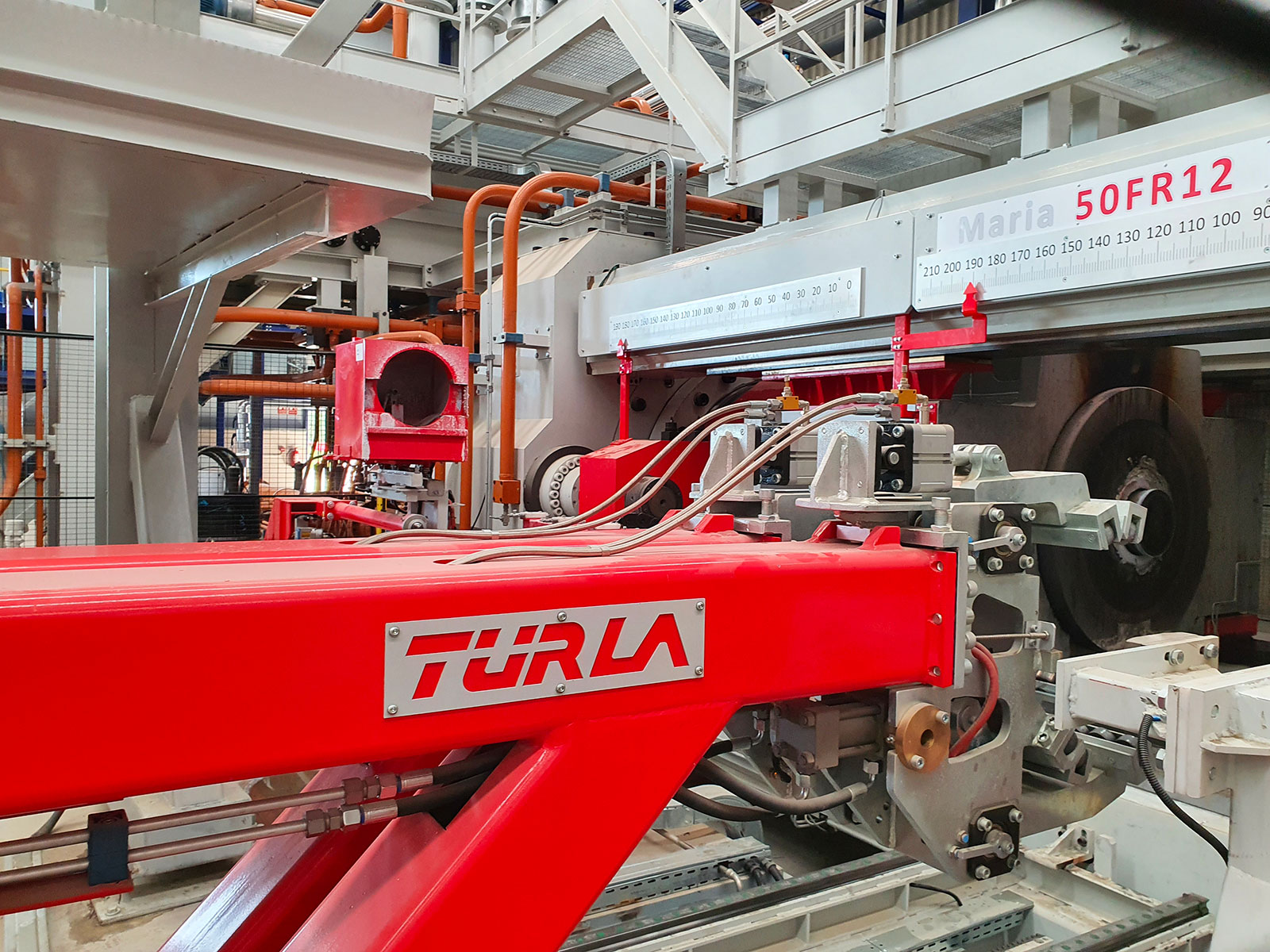

In a significant leap forward for the manufacturing industry, the commissioning of a cutting-edge 10-inch extrusion press marks a milestone in the pursuit of enhanced production capabilities and technological innovation. The state-of-the-art press, heralded as a game-changer in the field of extrusion, promises to revolutionize the way aluminum products are manufactured and delivered to market.

Addressing the audience, Our Chairman underscored the importance of technological advancement in driving growth and competitiveness in today's dynamic market landscape.

"We are thrilled to announce the commissioning of our new 10-inch extrusion press, a testament to our commitment to innovation and excellence," said by our chairman. "This investment underscores our dedication to meeting the needs of our customers while staying at the forefront of technological advancement in the industry."

The new 10-inch extrusion press represents a significant upgrade in capacity and efficiency, boasting advanced features and capabilities designed to meet the evolving demands of customers across various industries. With its enhanced throughput and precision engineering, the press is poised to streamline production processes, reduce lead times, and elevate product quality to new heights.

The introduction of the 10-inch extrusion press is expected to have far-reaching implications for EAEF's operations, enabling the company to tackle larger projects, accommodate diverse customer requirements, and expand its product offerings. Moreover, the press's energy-efficient design and sustainable manufacturing practices align with EAEF's commitment to environmental stewardship and corporate responsibility.

The public response to the announcement has been overwhelmingly positive, with clients expressing anticipation for the enhanced capabilities and benefits that the new press will bring. "We are excited about the possibilities that the new 10-inch extrusion press presents," remarked a longstanding customer. "With increased capacity and efficiency, we look forward to even greater collaboration and success with EAEF."

As EAEF embarks on this new chapter of growth and innovation, the commissioning of the 10-inch extrusion press underscores its position as a leader in the industry and reaffirms its commitment to driving progress and delivering value to customers worldwide. With its sights set on the future, EAEF is poised to continue pushing boundaries and setting new standards of excellence in extrusion manufacturing.

In a momentous occasion for the manufacturing industry, a brand-new aluminum extrusion factory has opened its doors, heralding a new era of innovation and production excellence. EAEF has already begun operations with resounding success, positioning itself as a frontrunner in the field of aluminum extrusion.

Situated in 3rd Industrial City, the factory boasts cutting-edge technology and advanced machinery, meticulously designed to streamline production processes and meet the growing demand for high-quality aluminum products. From architectural frameworks to various innovative components, EAEF is poised to cater to diverse industry sectors with its versatile extrusion capabilities.

In his address, Our Chairman emphasized the factory's commitment to excellence and sustainability, highlighting its adherence to stringent environmental standards and responsible manufacturing practices.

Since its inception, EAEF has wasted no time in making its mark in the industry. With a team of skilled professionals at the helm, the factory has already commenced operations with several successful production runs, delivering exceptional results in terms of product quality and efficiency.

Customer feedback has been overwhelmingly positive, with clients praising EAEF for its prompt delivery, attention to detail, and unwavering dedication to customer satisfaction. "We are thrilled to partner with EAEF for our aluminum extrusion needs. Their commitment to quality and reliability sets them apart in the industry," remarked a satisfied client.

Looking ahead, EAEF is poised for continued success, with plans to expand its product offerings, enhance operational capabilities, and forge strategic partnerships to further solidify its position in the market. With innovation at its core and a steadfast commitment to excellence, EAEF is set to redefine the standards of aluminum extrusion manufacturing for years to come.